Accuform Polymers Addition is Nearing Completion!

Accuform Polymers, a long-standing leader in custom plastics manufacturing, has proudly called Warsaw, North Carolina home for decades. As their business has expanded, so has their need for additional space—a familiar challenge for companies experiencing consistent, healthy growth. Fortunately, when Accuform first opened its doors, the team occupied only a small portion of their 30,000-square-foot pre-engineered metal building. Early expansions were as simple as spreading into unused sections of their own facility.

Today, however, after adding seven state-of-the-art rotational molding machines, three heavy-gauge thermoformers, and three CNC routers, that once-ample space is now fully utilized. So when the time came to upgrade one of their machines to a newer, larger, and more efficient model, the company needed more than just a rearranged floor plan—they needed a true expansion.

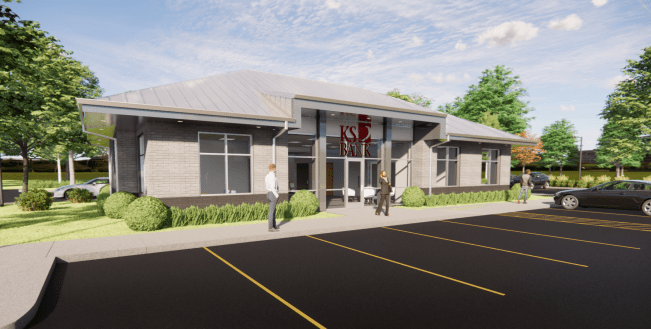

To bring this next step to life, Accuform partnered with Gontram Architecture and Ten Penny Construction to design and construct a seamless addition to their existing facility. The video above captures the progress, including the pouring of structural slabs and footings and the erection of the pre-engineered metal building expansion. The project also includes an additional 3,000-square-foot exterior concrete slab, giving Accuform the space required to support their exciting new equipment upgrade.

Construction began in early October and remains on track for completion by mid-November.